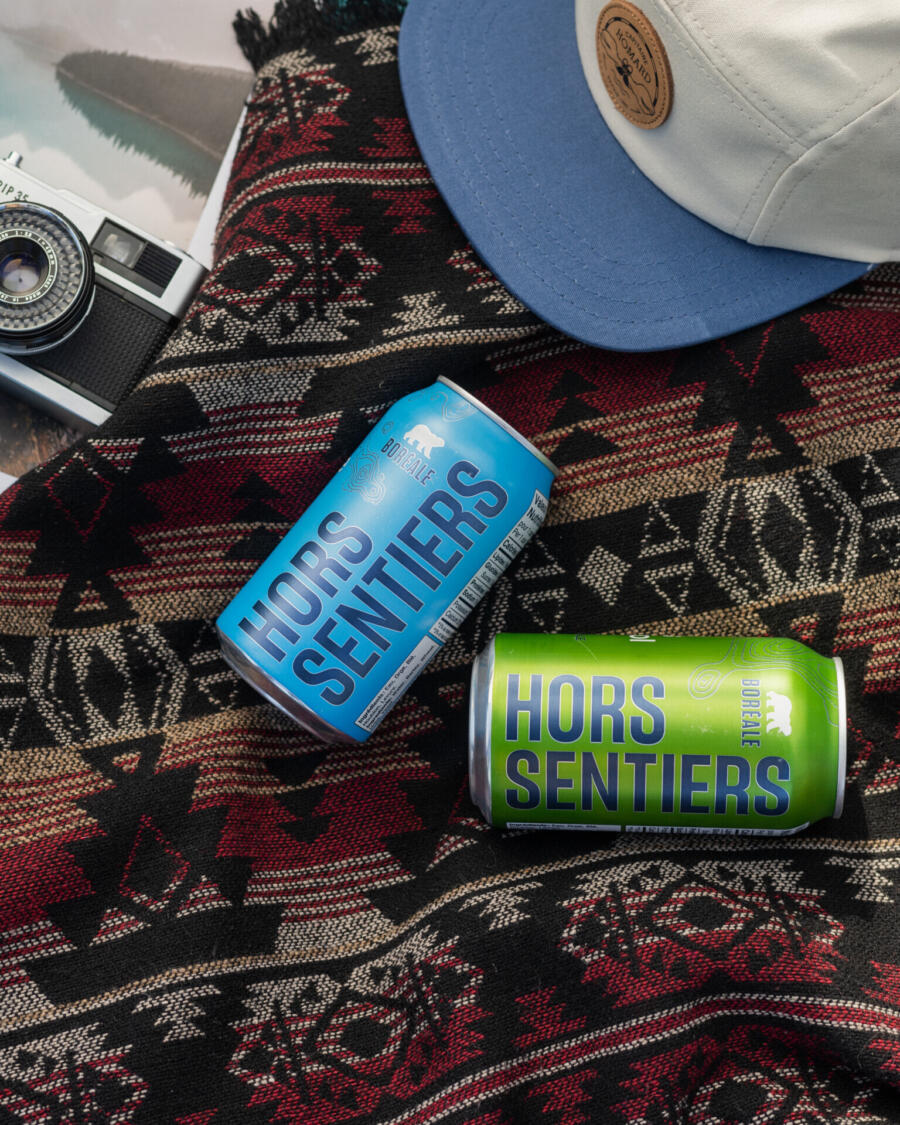

Our products

The Boréale Microbrewery

An exceptional microbrewery built one sip at a time. Every one of our creations at is a new chapter in its rich history.

Our storyWhat's new

#BiereBoreale

Boréale: Happiness in every sip.

Shop Boréale

To help you find our specialty beers, we've made some temporary changes to our processes at Relais Boréale. From now on, we offer a contactless experience inside the Relais Boréale! Our pre-order is always available in the SHOP section to save you time on site! Discover our products available here:

Discover our productsRelais Boréale - Update!

Our Relais is open from Tuesday to Saturday from 10 a.m. to 6 p.m.